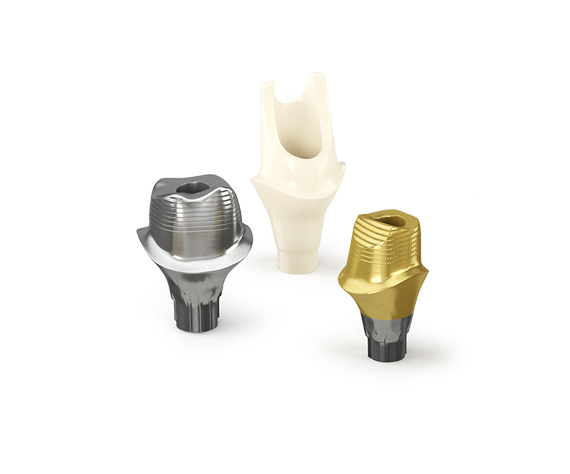

Individual supports, as their name suggests, are manufactured individually for each patient. These supports are milled precisely to fit the structure of the patient’s tissue. The individual support tilts the direction of the prosthesis, the screw is attached to the implant, and the prosthesis is cemented. The connection can be with or without geometry.

It is usually made of titanium, rarely of zirconium. High-quality individual support must maintain precise tolerance limits (all exact dimensions) and a smooth polished surface.